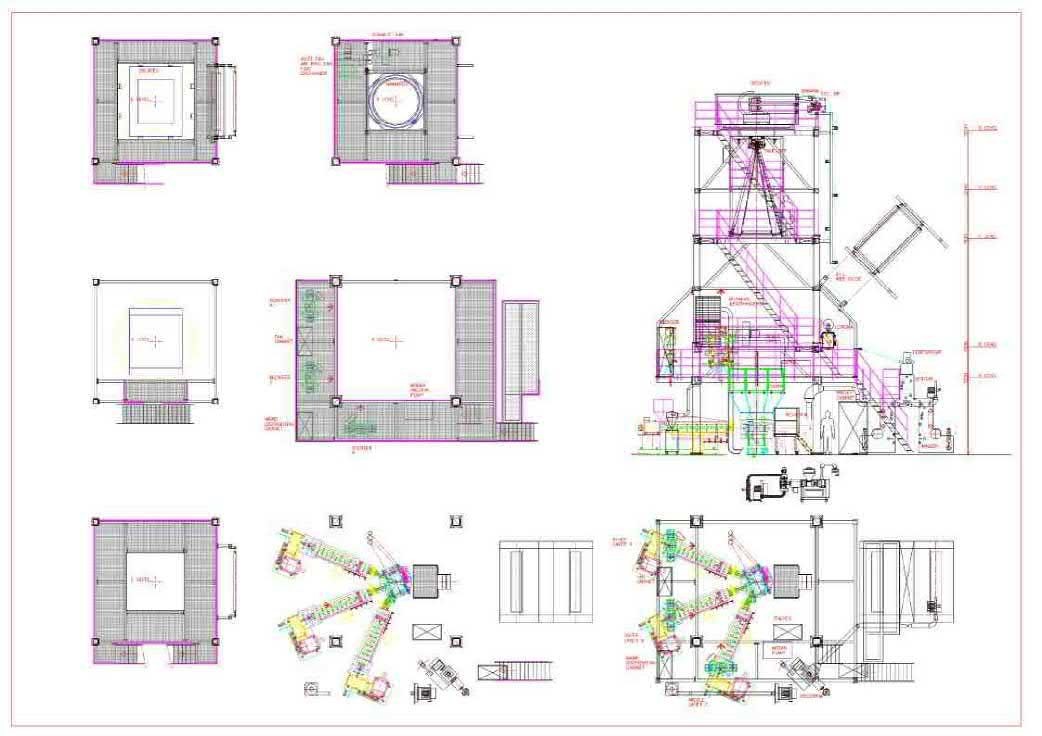

Extruder Coex 3layer

GENERAL TECHNICAL SPECIFICATIONS

- 2x90mm Heavy Duty extruder units with Manual Screen Changer, 93kW AC Drive

- 1x90mm Heavy Duty extruder unit with Manual Screen Changer, 112kW AC Drive

- Three 4-component (1main+3components) Gravimetric Blender

- Ø325mm 3-Layer IBC Stack Type die complete with Auto Gap Control

- Dual Lip Air Flow “Eliminator” Cooling Ring with AC Blower, Heat Exchanger & Piping

- IBC (Internal Bubble Cooling) System with AC Blowers, Heat Exchanger & Piping

- 500-2600mm layflat Bubble Stabilizing Cage

- 500-2600mm layflat Bubble Plenum

- 2500mm Horizontal Oscillating Haul-Off Unit complete with full Gusseting Tools

- 2500mm 8kVA Corona Treating station (optional)

- 2500mm E&L Web guiding System

- 2500mm Secondary Nip Station

- 2500mm Double Back to back Automatic Macchi Surface Winders

- Two (2) 2500mm Banana type Spreader Rubber Rolls

- Twelve (12) 2500mm Aluminum Idler Rollers

- ITALYCS ®IV PLC based Control Cabinet with Host PC , SCADA, Network connectivity and Touch Screen to control all the line components

- Recotrim Trim Recovering System complete with Venturi, Blower & Piping

- Steel Frame (Tower) approx Height 12m

- Line speed 5-180m/min, 450kg/h max output rate, +/-7%(+/-5 with Autogage Option)

- 2Σ web thickness variation (depending on Gap and raw materials)

- 2400mm max final web width, 2600mm gusseted, 20-200 micron thickness

- Raw Materials: LDPE, LLDPE, EVA, HDPE, PP, PA, Metalocenes, in pellets

- Products: Shrink Film, Mulch Film, Stretch Film, Stretch Hood Film, Industrial Film